How long does epoxy floor take to dry?

January 6, 2025Regarding commercial kitchen flooring Brisbane, hygiene, safety, and durability are first concerns. Flooring for a busy kitchen needs to be easy to clean and slip-resistant yet able to tolerate high temperatures, spills, and heavy foot activity.

The right flooring solution guarantees compliance with health criteria and improves worker safety regardless of the size of your restaurant, café, or catering company.

Brisbane companies may discover the ideal mix of utility and style to fit their requirements from the several choices of epoxy and resin flooring. Let’s take a deep look at it.

Why should we use epoxy commercial kitchens?

Epoxy flooring is among the best choices for commercial kitchen flooring Brisbane has available because of its lifespan, hygienic features, and safety factors. In a busy kitchen, flooring needs to be easily cleaned and slip-resistant, as well as withstand high temperatures, spills, grease, and heavy foot traffic.

Epoxy resists stains, satisfies health and safety regulations, and provides a smooth, non-porous surface, preventing bacterial growth. Its lifespan provides likewise long-lasting performance, thereby reducing maintenance expenses.

For business kitchens in Brisbane looking for a consistent, high-performance flooring solution, epoxy is the best choice.

The best type of epoxy for commercial kitchens

Choosing the suitable epoxy for commercial kitchen flooring Brisbane guarantees a long lifespan, safety, and hygienic conditions. The best epoxy flooring available for commercial kitchens is:

- Perfect for busy kitchens, epoxy mortar flooring is the strongest epoxy option and quite resistant to impact, heat, and chemicals.

- Combining epoxy glue with quartz grains produces remarkable slide resistance, therefore ensuring safety in wet and oily environments.

- Easy to clean, self-leveling epoxy creates a perfect, seamless surface impervious to stains and bacterial development.

These epoxy selections provide commercial kitchens with long-lasting, hygienic, low-maintenance solutions that meet health criteria and guarantee a safe workplace.

Maintenance tips

Having commercial kitchen flooring Brisbane guarantees hygienic conditions, safety, and durability. Not only does a floor maintained in good shape meet health criteria, but it also boosts workplace efficiency. This is a closer look at your industrial kitchen flooring:

Planned Regular Cleaning

- Frequent floor sweepers help to remove food waste, loose dirt, and grease accumulation.

- Keeping the floor intact, use a pH-neutral cleaner and a moist mop loaded with warm water.

- Strong chemicals like ammonia or bleach should be avoided since they could destroy the surface of epoxy or resin flooring.

Fast Spill Clean-up

- Commercial kitchens commonly leak oil, water, sauces, and other substances.

- Clean spills right away to prevent staff slip hazards, stains, and smells.

- Stop accumulation from oil spills with absorbent products or degreasers.

Preventive Action and Non-Slip Matting

- Put non-slip rubber mats around high-traffic areas and kitchen stations to reduce wear and tear.

- Use protective floor pads under heavy machines to prevent flooring from creasing or denting.

Deep Cleaning and Degreasing

- Deep clean the floor using professional-grade tools—an auto-scrubber or pressure washer at least once a week—to get tough grease and grime.

- To avoid surface damage, make sure the degreaser you use matches epoxy flooring.

Regular Maintenance and Corrections

- Look especially in highly used areas for wear including discoloration, peeling, or cracking.

- Small cracks or chips should be taken quick care of to prevent greater damage and maintain a perfect surface.

- Applying a protective epoxy finish will assist the floor’s lifetime to be extended.

Avoid hauling bulky machinery

- Moving shelves or appliances should be done so cautiously since dragging them across the floor could cause scrapes or cracks.

- Using furniture sliders or lifting techniques, move large pieces safely.

Provide suitable drainage

- Many times, found in commercial kitchens, are wet spots; make sure floor drains are free from obstacles and allow enough water flow.

- Standing water can erode the epoxy coating over time; so, proper floor drying is rather important.

Following these maintenance tips for commercial kitchen flooring Brisbane enables businesses to ensure that their flooring is durable, slip-resistant, and readily cleanable. A well-kept kitchen floor increases safety, satisfies health regulations, and provides long-term cost savings by reducing the demand for frequent repairs.

Regulations & Compliance for Kitchen Flooring in Brisbane

Companies laying commercial kitchen flooring Brisbane have strict guidelines to ensure safety, hygienic conditions, and lifetime. These guidelines are followed by local health authorities and occupational safety groups to maintain high standards in sectors of food processing. Here we break out the main compliance needs:

Safety Regulations and Slip-Resistance

Slip-resistant commercial kitchen flooring is required to prevent mishaps compliant with Workplace Health & Safety Queensland (WHSQ) policies. Australian Standard AS 4586 specifies slip-resistance levels for different environments; hence, flooring should meet it.

Usually used to increase grip and safety are epoxy packed with quartz, textured surfaces, or non-slip coatings.

Resistance and Durability of Influence

Commercial kitchen flooring has to withstand hot spills, heavy foot traffic, and tool or machine contact. Materials including polyurethane resin or epoxy mortar floors provide outstanding long-term performance and durability.

Right water resistance and drainage

Waterproof flooring is quite important in moist surroundings to prevent damage and bacterial growth. Flooring should follow local government guidelines and include suitable drainage systems to prevent water pools and slip risks.

Perhaps little slopes would be required to correctly direct water toward drains.

Heat & Fire Resistance

If flooring is to survive high oven and stovetop temperatures, it must be heat-resistant. There are several epoxy and resin coatings designed to resist thermal stress and fire hazards.

Following Food Safety Policies

Food Standards Australia New Zealand (FSANZ) Code on food-safe flooring has Brisbane companies following.

By not absorbing bacteria, grease, or smells, flooring offers a safe and clean food preparation space. Commercial kitchen flooring Brisbane regulations followed determined safety, hygienic standards, and operational effectiveness.

Choosing quality, food-safe, slip-resistant flooring not only meets legal criteria but also extends the lifetime and use of your kitchen. Dealing with trustworthy flooring experts will help businesses negotiate regulatory requirements and select the best flooring solutions for their specific needs.

Choosing the Right Flooring Contractor in Brisbane

One has to hire the best contractor to provide a compliant, safe, and long installation for commercial kitchen flooring Brisbane. Professional flooring experts will help you choose suitable materials, meet local standards, and provide your company kitchen with a long-lasting solution. These key components should assist in your flooring contractor selection:

Knowledge and Experience

- Look for contractors with a lot of commercial kitchen flooring knowledge, especially with epoxy and resin flooring Brisbane.

- Examine their body of past work to assess their quality.

Compliance with Industry Standards

- Check the contractor follows Food Standards Australia New Zealand (FSANZ) and Workplace Health & Safety Queensland (WHSQ), Australian safety and health criteria.

- Ask whether their flooring selections meet slip-resistance criteria and food-safe, non-porous, chemical-resistant standards (AS 4586).

Quality of the materials and installation technique

- By offering superior materials including epoxy, polyurethane, or resin flooring packed with quartz, dependable contractors will guarantee lifespan and hygienic conditions.

- Professional installation helps to prevent over-time water damage, flaking, or cracks.

Flexibility and Adaptability

- Choose a contractor that offers unique flooring choices based on traffic, humidity, and specific kitchen needs.

- They should have smooth finishes, heat-resistant options, and anti-slip coatings for best performance.

Client Reviews and Reputation

- Review internet assessments and client quotes from earlier jobs to gauge the contractor’s dependability and customer service.

- Get references or review their ratings on Houzz on company directories, Google Reviews, or local trade associations.

Warranty Services and Aftercare

- A qualified contractor will offer long-term satisfaction by means of material and workmanship guarantees.

- Ask about recoating options, repairs, and maintenance to help your kitchen flooring last as it should.

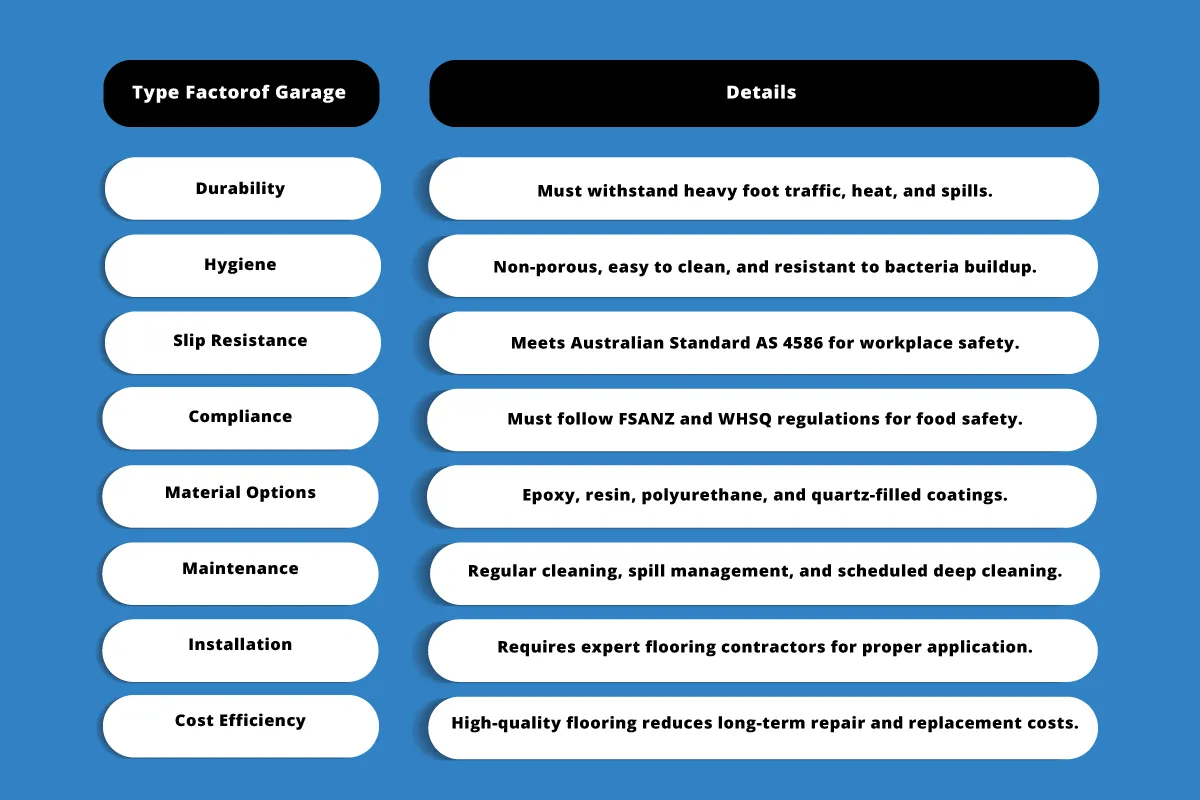

Key Considerations for Commercial Kitchen Flooring Brisbane

This table provides a quick overview of the essential factors to consider when selecting commercial kitchen flooring Brisbane for safety, durability, and compliance.

Ensuring the Best Commercial Kitchen Flooring in Brisbane

Ensuring the Best Commercial Kitchen Flooring in Brisbane

Choosing suitable commercial kitchen flooring Brisbane can help you to keep a safe, clean, long-lasting workplace. Whether epoxy, resin, another durable material, another flooring solution—you can ensure compliance with Australian safety regulations and improve kitchen efficiency.

Correct installation, working with a skilled flooring contractor, and regular maintenance will help your floors survive longer, so reducing long-term costs and hazards.

Purchasing high-quality commercial kitchen flooring can enable Brisbane businesses to provide their staff members and customers a safer, cleaner, and more efficient surroundings.

FAQs About Commercial Kitchen Flooring Brisbane

1. Which flooring type is best for a Brisbane commercial kitchen?

The best options for commercial kitchen flooring Brisbane are epoxy, resin, polyurethane and polymers flooring. High traffic kitchens would find these strong, slip-resistant, and readily cleaned materials ideal.

2. How can I maintain the commercial kitchen flooring?

Regular sweeping, pH-neutral cleanser mopping, and deep cleaning with professional equipment help to maintain the floor. Its lifetime is extended in part by planned inspections and fast spill cleaning.

3. Does the flooring in a commercial kitchen have to follow specific guidelines?

Commercial kitchens flooring must, indeed, comply with Food Standards Australia New Zealand (FSANZ) and Workplace Health & Safety Queensland (WHSQ.). They should be non-porous, AS 4586 slip-resistant, easy to clean.

4. Commercial epoxy flooring has what lifetime?

With proper care, epoxy and resin flooring can last 10–15 years or more depending on foot activity and use. Its lifetime is raised with regular maintenance and professional recoiting.

5. Flooring for a commercial kitchen would cost Brisbane what?

The flooring choice, kitchen size, and required preparation influence the cost. Epoxy and resin flooring are rather competitively priced long-term investments given their low upkeep and lifespan. See a qualified contractor for a reasonable quote; this will help you.